Position:Home > Products & Services > SST™ Standard Systems

> SST PX & EPX

SST™ PX & EPX

Introducing the PX & EPX Cold Spray Systems

The PX system incorporates improvements to the proven first-generation Series P systems, including a newly designed integrated powder feeder. The PX is ideal for spraying the full range of commercial powders and powder blends available from CenterLine.The EPX system is an upgrade to the Series EP machines and now comes with a newly designed integrated powder feeder system. It is designed for higher gas pressure capability to accommodate harder materials and with greater deposition efficiencies. The EPX is ideal for spraying aluminum alloys, austenitic stainless steels, nickel, and nickel alloys.

The next generation of SST™ Cold Spray systems integrate the latest powder feeder technology:

- Non-pressurized feeding

- Powder does not clog the feeder

- Low maintenance design

- Powder feed consistency is independent of powder fill levels for dependable application performance

- Feeders can easily be removed and filled in glove box or ventilated area

- Less than 10 minutes needed for powder changeover

- Feeder swap within 5 minutes to optimize run-time

- Double canister design with powder volume capacity of 1000 ml per canister

- Powder feed rate up to 120 g/min compared to 80 g/min for the previous design

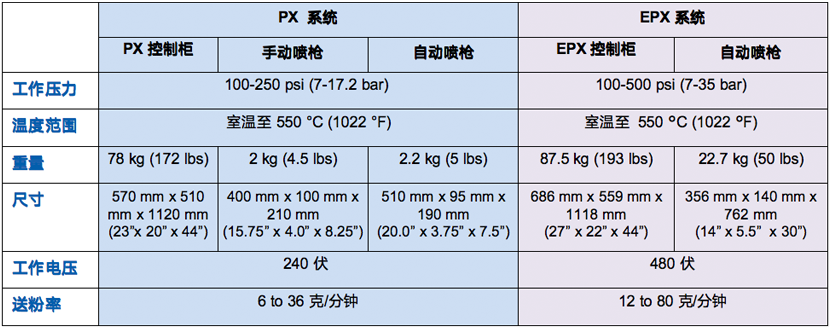

Technical Specifications

Contact CenterLine for detailed specifications or any additional technical information required.

SST Spray Guns*

*US Patent 8,313,042.

Robotic Spray Gun

Customers who desire to automate their Cold Spray application may select an SST Automatic Spray Gun. This spray gun comes with a stainless steel outer shell for durability and lightweight. It is offered with a 4.25 kW heater to satisfy a range of application requirements.Manual Spray Gun

The manual spray gun outer shell is made of a heat and impact-resistant polymer. Its ergonometric design has been optimized to meet durability, weight, and balance for manual operation.A single ON/OFF toggle switch button is provided on the handle to start/stop spraying. A Powder Feeder selection button is also provided to either spray powder or air only; this is a dual button and allows right or left-handed operators to use the manual gun with ease.

A powerful 3.8 kW heater is a key component of the manual spray gun unit. The heat rise time to the preset value is fast so that there is a minimal delay between pushing the trigger and actual spraying. This optimized design maintains a constant spray temperature during operation allowing for trouble-free performance. A snap-on nozzle guard protects against touching the hot nozzle and related components.

The hand-held spray gun is perfect for line-of-sight applications. The operator has complete control of the coating position and profile, being allowed to have an immediate response to spray angle and stand-off distance variations.